12th iteration still fails. Submission is in 3 hours. The error message makes no sense. Welcome to mechanical engineering.

You’ve redrawn the assembly four times. The simulation keeps crashing at 87% completion. Your constraint errors multiply like rabbits every time you think you’ve fixed them. The 3D model that looked perfect on your screen renders with impossible intersections. And now, with the deadline breathing down your neck, SolidWorks has decided to freeze completely.

You restart. Pray. Try again.

This is the reality nobody mentioned during orientation. Mechanical engineering isn’t just about understanding forces and materials—it’s about maintaining your sanity while software actively works against you, deadlines compress impossibly, and your entire semester grade depends on whether your laptop decides to cooperate tonight.

Recent research shows that over 55% of college students experience some degree of academic burnout, with 75% feeling overwhelmed by their academic workload. For mechanical engineering students specifically, studies identify engineering workload as a defining stressor that differentiates the field from other disciplines.

You’re not failing. The system is.

Let’s examine the five silent battles mechanical engineering students fight every single day—and research-backed strategies to survive them without sacrificing your mental health or your passion for engineering.

1. The CAD Software Betrayal (When Technology Becomes Your Enemy)

Your Model Worked Yesterday. Today It Doesn’t. Nothing Changed. Everything Changed.

You spend three hours perfecting an assembly. Every part mates correctly. The dimensions are exact. You save, close, and celebrate a small victory.

The next morning, you open the file. Sixteen rebuild errors. Your carefully constrained sketch is suddenly over-defined and under-defined simultaneously—a feat that should be mathematically impossible. Parts that were perfectly mated now float in digital space, mocking your efforts. The undo button offers no salvation.

CAD software is supposed to be a tool. Instead, it feels like a malicious entity designed to test your patience and destroy your sleep schedule.

The Research Says: A study in the International Journal of STEM Education found that engineering students experience a normalized stress culture where high stress is not only common but expected. The researchers developed measurement tools specifically for engineering stressors, recognizing that technical tool challenges represent a unique category of academic stress not found in other disciplines.

Your Mindful Survival Strategy:

- Save Incrementally With Version Numbers: Before making any significant change, save your file as “Project_v23” instead of overwriting. When disaster strikes, you can revert to the last working version instead of starting from scratch. This takes five seconds but saves hours of reconstruction work.

- Expect Software Failure: Budget an extra 40% time cushion for every CAD project. Not because you’re slow—because the software will fail at the worst possible moment. This isn’t pessimism; it’s risk management based on consistent historical data (your entire experience so far).

- Document Your Process: Keep a simple text file noting what constraints you applied and why. When the model breaks mysteriously, you have a roadmap back to functionality instead of guessing which of 47 constraints is causing the cascade failure.

- Learn the Emergency Fixes: Every CAD platform has its quirks. Spend 30 minutes learning the common error patterns for your software. Knowing that “closing and reopening the file” or “rebuilding in a specific order” fixes 80% of issues reduces panic when deadlines loom.

- Reframe Technical Failure: Every software crash is teaching you troubleshooting skills that working engineers use daily. In your future career, you’ll spend significant time debugging technical problems. Consider this involuntary but valuable training.

3-Minute Frustration Dump Voice Note (Delete After):

When your software betrays you and rage is building, record a voice note on your phone. Vent everything—the unfairness, the frustration, the exhaustion, the specific ways this software is terrible. Use profanity if needed. Get it out uncensored for three full minutes.

Then delete it immediately.

This practice, supported by emotion regulation research, allows you to fully express frustration without directing it at people (or yourself). The deletion ritual signals closure: you acknowledged the emotion, now you’re moving forward. This clears mental space for problem-solving instead of letting frustration compound into helplessness.

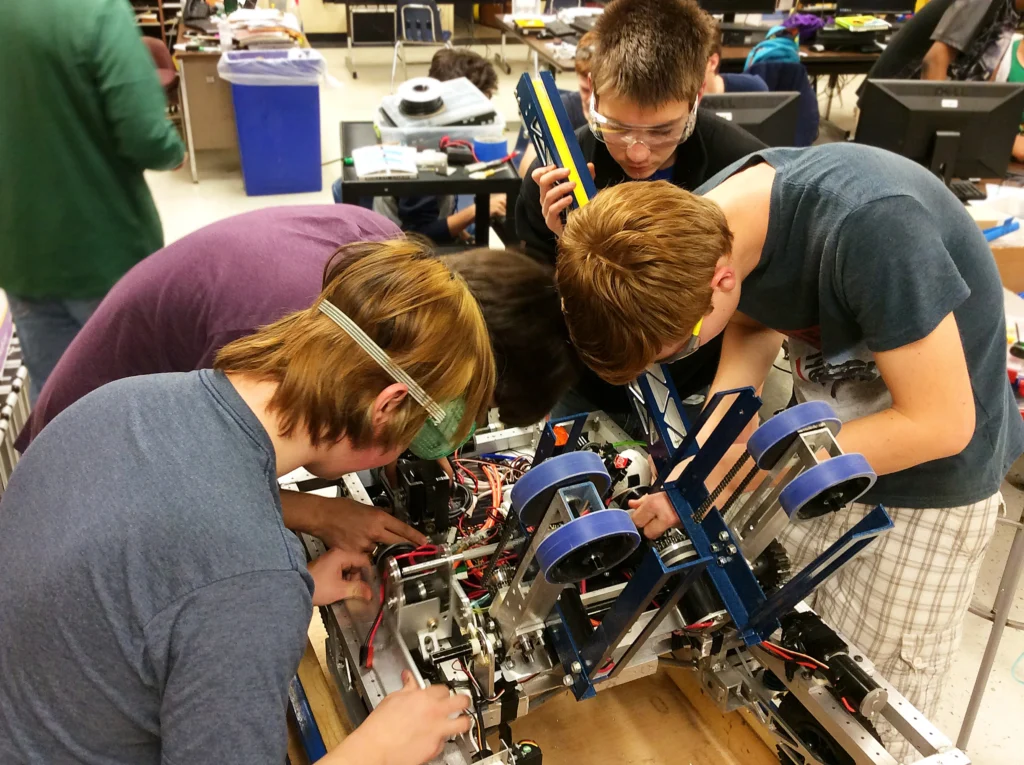

2. The Workshop Intimidation Factor (When Everyone Else Seems to Know What They’re Doing)

You’re Googling “Which End of the Wrench Do I Use” While Your Partner Machines Complex Parts

The workshop is loud, industrial, and filled with machines that could remove fingers if misused. Everyone around you seems comfortable—adjusting speeds, selecting tools, making precise cuts. Meanwhile, you’re trying to remember which direction loosens a bolt while pretending you totally know what you’re doing.

Your lab partner completes their machining in 40 minutes. You’re still measuring for the third time because you keep second-guessing yourself. The demonstrator watches, and you feel the weight of judgment even if none exists.

The Research Says: Research on engineering stress culture found that female students report significantly higher levels of stress and anxiety in engineering contexts, while first-generation students experience higher depression levels. The competitive comparison inherent in shared laboratory environments amplifies these stress patterns, particularly for students who feel they don’t naturally belong in mechanical spaces.

Your Mindful Recalibration:

- Everyone Started Somewhere: That confident student? They either had previous workshop access (privilege you may not have had) or they’re faking confidence as hard as you are. Competence isn’t inherent—it’s built through repeated exposure. Give yourself permission to be a beginner.

- Ask Questions Early: Instructors and teaching assistants would rather answer a basic question than watch you waste material or risk injury. Phrasing matters: “Can you verify my setup before I start?” sounds professional and safety-conscious, not incompetent.

- Focus on Your Process, Not Others’ Speed: Machining isn’t a race. A slow, accurate part beats a fast, incorrect one every time. Professionals prioritize precision over speed because rework wastes more time than careful initial work.

- Practice During Off-Hours: If your workshop has open access times, use them. Twenty minutes of practice without pressure or comparison builds confidence faster than any lecture. Familiarity reduces intimidation.

- Document Your Learning: Take photos of proper setups. Record correct speeds and feeds. Build a personal reference guide. Future-you will thank present-you, and the act of documenting shifts your mindset from “I’m bad at this” to “I’m building expertise.”

3. The Perpetual Project Pile (When Everything Is Due At Once, Always)

Design Project, Lab Report, Thermodynamics Assignment, Machine Design Quiz—All This Week

Monday: Machine design project draft due.

Tuesday: Thermodynamics assignment and manufacturing lab report.

Wednesday: Materials science quiz.

Thursday: Fluid mechanics problem set.

Friday: CAD assembly final submission.

Saturday: Catch up on everything you couldn’t finish during the week.

Sunday: Pretend you’ll rest, but actually start next week’s workload.

Repeat until graduation or breakdown, whichever comes first.

The mechanical engineering curriculum seems designed by people who forgot that time is linear and students are not, in fact, machines capable of unlimited parallel processing.

The Research Says: Qualitative research consistently identifies engineering workload as the most frequent and severe stressor experienced by engineering students, with students describing workload as the defining characteristic that differentiates engineering from other majors. This isn’t individual weakness—it’s a structural curriculum design issue.

Your Mindful Resource Management:

- Triage Ruthlessly: Not everything deserves equal effort. Identify which assignments impact your grade most significantly and allocate time proportionally. A project worth 30% of your grade deserves more attention than a homework set worth 5%. This isn’t laziness—it’s strategic resource allocation.

- Good Enough Is Good Enough: Perfectionism will destroy you in engineering. Aim for “meets requirements and demonstrates understanding” rather than “absolute perfection.” The difference between 85% and 95% effort often yields only a 2-3% grade improvement but costs double the time.

- Batch Similar Tasks: Complete all CAD work in one focused block. Do all calculations in another. Context-switching between different types of work wastes cognitive energy. Batching reduces mental friction and increases efficiency.

- Use Dead Time Strategically: Waiting for a simulation to run? Start the next assignment. Machining a part that takes 15 minutes? Review formulas for tomorrow’s quiz. Engineering often involves waiting—use those gaps instead of letting them fragment your day.

- Communicate With Professors: If truly everything converges impossibly, talk to instructors before the deadline. Most are reasonable humans who understand scheduling conflicts. Asking for help isn’t weakness—it’s professional problem-solving.

2-Minute Shoulder Rolls + Sigh:

When deadlines feel crushing and your body is physically tense, try this physical reset:

- Stand or sit comfortably

- Roll your shoulders backward in slow, exaggerated circles (5 times)

- Roll them forward (5 times)

- Raise both shoulders to your ears, hold for 5 seconds

- Drop them suddenly while exhaling forcefully with an audible sigh

- Repeat three times

This releases physical tension that accumulates during stress, signals your nervous system to downshift from fight-or-flight mode, and takes only two minutes but noticeably reduces the physical sensation of being overwhelmed.

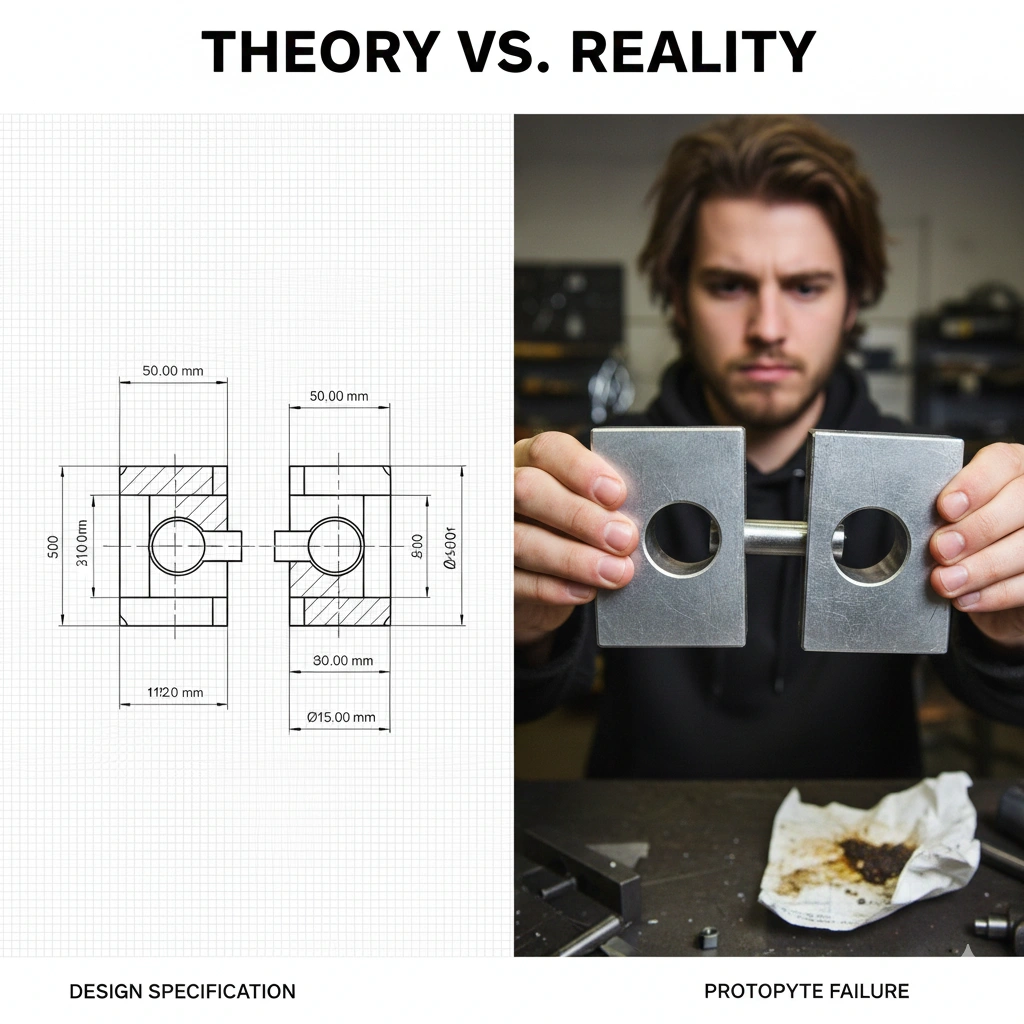

4. The Theory-Practice Chasm (When Math Doesn’t Explain Why Your Part Won’t Fit)

The Calculation Says It’ll Work. The Physical Part Disagrees. Loudly.

Your calculations are flawless. The tolerances account for thermal expansion. The FEA simulation shows green (safe) stress distribution. The technical drawings are dimensionally perfect.

Then you manufacture the actual part. It doesn’t fit. Or it fits but binds. Or it fits perfectly but fails under load in ways the simulation never predicted. The gap between theoretical mechanical engineering and physical reality is where optimism goes to die.

The Research Says: Studies on engineering student stress attribute difficulties to multiple factors including long hours with computers, academic performance concerns, and the challenge of translating theoretical knowledge into practical application. This theory-practice gap represents a fundamental tension in engineering education that students must navigate repeatedly.

Your Mindful Bridge-Building Strategy:

- Expect Real-World Deviation: Manufacturing isn’t perfect. Materials have inconsistencies. Machines have play. Tools deflect under load. Build mental models that include imperfection as normal, not failure. Your tolerance stack-up analysis should assume worst-case scenarios.

- Test Early, Test Often: Don’t wait until the final deadline to manufacture your first physical prototype. Make a crude version early to discover the problems while you still have time to redesign. Iteration is how engineering actually works.

- Ask “What Could Go Wrong?”: Before manufacturing, mentally walk through the process. Where could misalignment occur? Which dimensions are most critical? What’s your backup plan if this doesn’t work? Premortem analysis catches problems in the design phase, not during desperate last-minute assembly.

- Learn From Failure Fast: When something doesn’t work, investigate immediately while the context is fresh. What specifically failed? Why? What would prevent it next time? Treat each failure as data collection for your growing engineering intuition.

- Reframe the Gap: Industry engineers live in this gap permanently. Your frustration with theoretical models failing to predict reality is you learning what real engineering actually is—not applying perfect formulas, but navigating uncertainty with judgment and experience.

5. The Invisible Breaking Point (When “Fine” Becomes “Not Fine” Without Warning)

You’re Handling Everything Until Suddenly You’re Not Handling Anything

You’ve been managing. The workload is intense, but you’re keeping up. You’re tired, sure, but everyone’s tired. You’re stressed, but that’s just engineering culture, right?

Then one day, something minor goes wrong—a forgotten formula, a misplaced file, a professor’s offhand comment—and you completely fall apart. Tears come from nowhere. The thought of opening your laptop feels impossible. You can’t remember why you chose this major. You can’t imagine making it to graduation.

This isn’t drama. This is burnout finally becoming visible after weeks or months of invisible accumulation.

The Research Says: Research documents that 40% of students experiencing severe burnout reported significant grade drops, and 35% with chronic burnout symptoms considered dropping out entirely. Furthermore, a survey of engineering students found that 66% had symptoms of at least one mental health condition, but only 24% were officially diagnosed—revealing a massive gap between suffering and receiving support.

Your Mindful Recovery Protocol:

- Recognize the Signs Early: Emotional numbness, constant exhaustion despite sleep, inability to enjoy things you used to love, feeling detached from your goals, persistent irritability—these aren’t personal failings. They’re clinical symptoms of burnout requiring intervention.

- Take a Real Break: Not “scrolling social media while feeling guilty.” Not “watching Netflix with your laptop open.” An actual break where you give yourself permission to completely disengage from engineering for a defined period. Your brain needs genuine rest to restore cognitive function.

- Move Your Body: Research shows regular exercise is associated with a 30% reduction in burnout symptoms. Even 15 minutes of walking daily makes measurable differences in stress hormones and mental clarity. Your body and brain aren’t separate systems—moving one helps the other.

- Connect With Humans: Burnout isolates you. Fight that isolation intentionally. One meaningful conversation per day—about anything except engineering—rebuilds the social connections that buffer stress. You need reminders that you exist outside academic performance metrics.

- Seek Professional Support: If you’ve felt emotionally flat for weeks, if work that used to be challenging now feels impossible, if you’re having thoughts of self-harm or escape fantasies—talk to a counselor. Universities have mental health resources specifically for this. Using them isn’t weakness; it’s the engineering solution of bringing in the right tool for the problem.

- Remember Your Why: Before burnout buried it, you chose mechanical engineering for a reason. Maybe you loved building things. Maybe you wanted to solve environmental problems. Maybe you were fascinated by how machines work. That original spark still exists—burnout is covering it, not erasing it.

The Truth Behind The Deadlines: Your System Is Designed Poorly, Not You

Here’s what needs to be said clearly: mechanical engineering education has structural problems.

You’re expected to master complex theory, develop hands-on manufacturing skills, complete software-intensive projects, write detailed technical reports, and maintain high grades—all simultaneously, with minimal guidance on time management, mental health maintenance, or realistic workflow strategies.

Recent research specifically developed instruments to measure engineering stress culture, finding that high stress is not only common but normalized and expected within engineering education. This normalization means students interpret their struggle as personal inadequacy rather than recognizing systemic design flaws.

You’re not weak for finding this difficult. You’re human, operating in an environment that often treats burnout as a rite of passage rather than a problem to solve.

Your New Operating System: Practical Habits That Actually Work

Morning Grounding (3 minutes):

Before checking your phone or assignment list, sit quietly and take ten slow breaths. Set one intention for how you want to approach the day—not what you’ll accomplish, but how you’ll be. “Today I’ll be patient with myself when things don’t work.” “Today I’ll ask for help when I need it.” This creates internal stability before external chaos begins.

Project Start Ritual:

Before opening CAD or starting calculations:

- Save a new version file

- Set a timer for your planned work session

- Write down the specific goal for this session

- Close unnecessary tabs and notifications

This boundary-setting prevents the “I’ll just quickly check this” spiral that destroys three hours.

Physical Reset Every Hour:

Set a recurring timer. Every 60 minutes, stand up, stretch for 30 seconds, look at something far away to rest your eyes, and take five deep breaths. This isn’t wasted time—it’s preventive maintenance that keeps you functional for longer sessions.

Weekly Reality Check:

Every Sunday evening, honestly assess: Am I actually okay, or am I pretending to be okay? What do I need this week—more sleep, social connection, help with a specific topic, a real break? Planning self-care is as important as planning project timelines.

The Buddy System:

Find 2-3 classmates who share your values around sustainable work and mental health. Check in regularly. Share struggles, not just successes. Study together. Remind each other to eat and sleep. Collective resilience is stronger than individual endurance.

Final Blueprint: You’re Building More Than Projects

Right now, at this exact moment, you might be exhausted. You might be questioning your major choice. You might be wondering if everyone else finds this easier than you do.

They don’t. They’re just hiding their struggle while displaying their success, exactly like you are.

You chose mechanical engineering because something about designing, building, and understanding physical systems spoke to you. That passion is still there, underneath the CAD crashes and deadline stress and workshop intimidation.

This article is your reminder: You can become an engineer without destroying yourself in the process.

Try the shoulder rolls right now. Feel your body release some tension. That’s real. You’re here. You’re learning. You’re growing. That’s already success, even when it doesn’t feel like it.

These projects will end. These semesters will end. The specific CAD file that’s haunting you tonight will eventually stop mattering. But the person you’re becoming—the problem-solver, the designer, the engineer who doesn’t quit when systems fail—that person is permanent.

And that person deserves protection during this journey.

Take the frustration voice note when you need it. Do the breathing exercises. Save your work in versions. Ask for help without shame. Rest without guilt.

Take care of the engineer. The engineering will follow.

You’ve got this. And when you don’t, that’s okay too.

RESEARCH REFERENCES

- Crown Counseling. (2024). 30+ Eye-Opening Student Burnout Statistics That Demand Attention in 2024. Retrieved from crowncounseling.com/statistics/student-burnout/

- Mirabelli, E., Jensen, K., & Cross, K. J. (2023). Undergraduate student perceptions of stress and mental health in engineering culture. International Journal of STEM Education, 10(1), 1-19.

- Magana, D., Jensen, K., & Cross, K. J. (2025). Stressors and normalized stress in undergraduate engineering education culture: Development of the Engineering Stress Culture Scale and Undergraduate Engineering Stressors Questionnaire. International Journal of STEM Education, 12(1), 8.

- Jensen, K. J., & Cross, K. J. (2021). Engineering stress culture: Relationships among mental health, engineering identity, and sense of inclusion. Journal of Engineering Education, 110(2), 371-392.

- ASME. (2024). Mental Health in the Engineering Field. Official statement by Thomas Costabile, FASME, Executive Director/CEO. Retrieved from asme.org/topics-resources/society-news

- Poole, S., et al. (2023). Interventions to support the mental health and wellbeing of engineering students: A scoping review. European Journal of Engineering Education, 48(4), 567-589.

- Vitasari, P. (2011). Stress-related mental health issues in engineering students. International Journal of Psychological Studies, 3(2), 89-98.